A flexible metal hose is a flexible pipe made of stainless steel, commonly used to convey gas, liquid, steam, and other media. It features excellent flexibility through spiral or annular corrugated structures and provides high temperature resistance, high pressure resistance, corrosion resistance, and superior sealing performance.

Flexible metal hoses are ideal for solving installation constraints, absorbing system vibrations, and compensating for thermal expansion or misalignment. They are widely used in automation systems, hydraulic pipelines, chemical plants, HVAC systems, shipbuilding, and more.

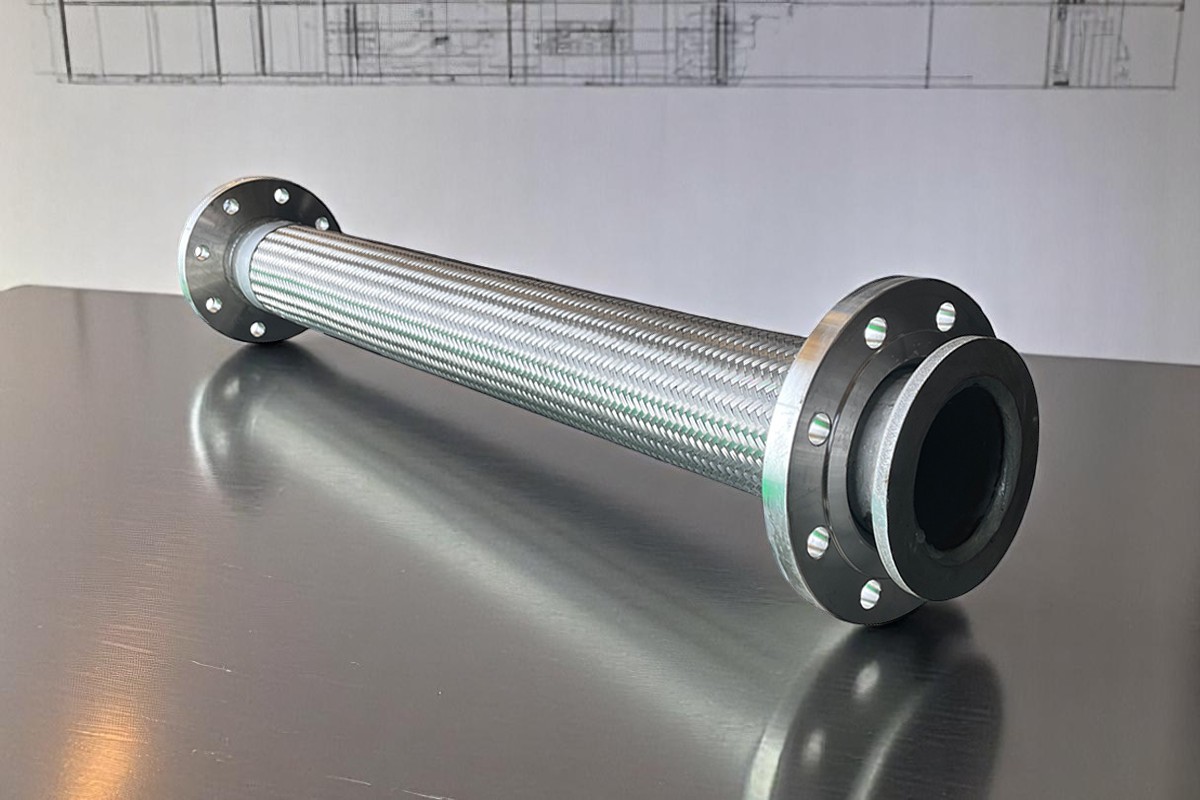

Corrugated Hose: The core component made of high-grade stainless steel. It carries pressure and allows bending and movement.

Braid Layer: A stainless steel wire braid that enhances pressure resistance and prevents the hose from elongating under pressure.

End Fittings: Include threaded, flanged, or quick-connect types to connect with other system parts.

Protective Sleeve or Spring Guard: Shields the hose from mechanical damage and extends service life.

Absorb system vibrations and mechanical shocks

Compensate for thermal expansion and contraction

Correct misalignments during installation

Maintain secure and leak-proof connections

Adapt to extreme operating conditions

For example, in high-temperature steam lines, rigid pipes may fail due to thermal stress, but flexible metal hoses can safely absorb displacement while maintaining a sealed connection.

Excellent flexibility and small bending radius

Corrosion-resistant for various media

High temperature and pressure tolerance

Superior fatigue resistance and long lifespan

Multiple connection types and easy installation

Customizable in length, diameter, and fittings

These advantages make flexible metal hoses an ideal choice for demanding industrial environments.

Petrochemical Industry: For transporting oil, chemicals, or corrosive media in a flexible and secure way.

Automation Equipment: Used to connect moving components and dampen vibrations.

Hydraulic Systems and Machine Tools: For high-pressure fluid transport under dynamic conditions.

HVAC Systems: As connections for hot or cold water and steam pipelines.

Shipbuilding: For fluid transfer in high-vibration environments.

Food & Pharmaceutical Industries: Using sanitary-grade stainless steel for contamination-free transport.

As automation and smart manufacturing advance, the demand for flexible metal hoses is growing, with notable trends including:

Lightweight and high-strength designs: Replacing traditional materials with advanced alloys.

Quick-connect technologies: Increasing popularity of easy-to-install connections.

Smart integration: Sensors for real-time monitoring of pressure, temperature, and flow.

Eco-friendly materials: Adopting recyclable and low-emission stainless steels.

Customization: Meeting application-specific needs with tailor-made specifications.

As a professional manufacturer of stainless steel flexible metal hoses, we provide:

A full range of standard sizes and models

Customization of hose length, diameter, and fitting types

Support for flange, threaded, welded, and quick-connect options

All hoses tested for pressure, sealing, and durability

Compliance with GB, DIN, ISO, ANSI, BS standards

Technical drawings and product selection guidance available

Our products are widely exported to Southeast Asia, the Middle East, Europe, and North America and are highly trusted by global customers.

If you’re looking for durable, corrosion-resistant, and flexible metal hoses for your system, contact us today. We’ll recommend the optimal product and offer competitive pricing based on your requirements.