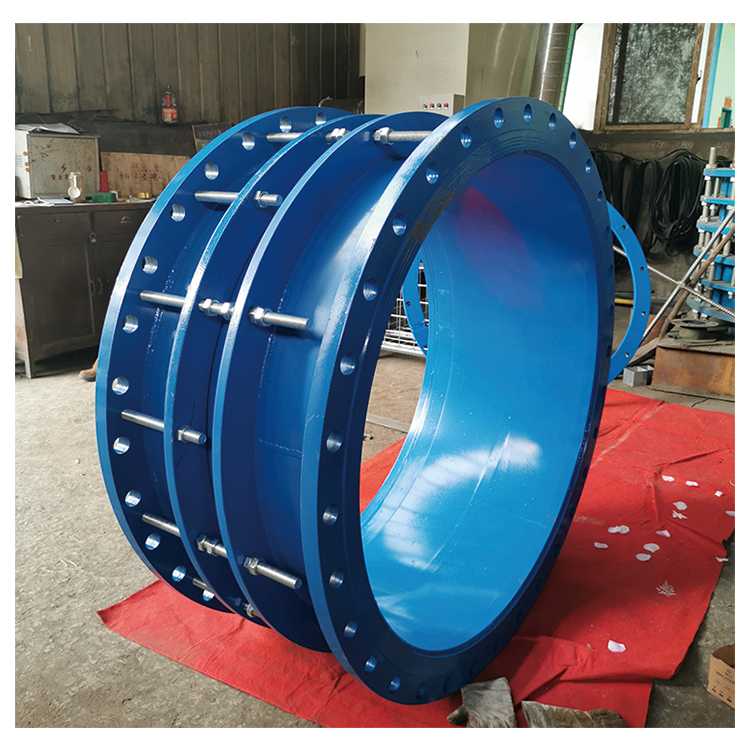

A Dismantling Joint is a pipeline component designed to facilitate easy installation, disassembly, and maintenance of pipeline systems. Its structure typically consists of a short pipe, flanges, tie rods, and sealing gaskets, allowing axial length adjustment and limited expansion. It is widely used in water plants, wastewater treatment facilities, pumping stations, petrochemical industries, and power plants, particularly for connecting pumps and valves.

The main advantage of dismantling joints lies in simplifying installation, compensating for pipeline alignment errors or thermal expansion, and greatly improving maintenance efficiency. It plays an essential role in ensuring the flexibility and reliability of modern pipeline networks.

Body: Made of carbon steel or stainless steel for excellent pressure resistance.

Flanged End: Connects with valves or pumps, supporting standards like PN10, PN16, ANSI, JIS.

Sleeve Pipe: Enables axial length adjustment during installation.

Tie Rods: Limit excessive expansion and ensure system safety.

Rubber Seal: Provides leak-proof connection and improves sealing performance.

Facilitates valve or pump installation/removal

Compensates for installation errors

Absorbs thermal expansion and contraction

Allows easy disconnection and reconnection for maintenance

Protects pipeline systems from mechanical stress

For example, installing a dismantling joint at a pump outlet enables rapid pump replacement without altering the pipeline system, saving time and labor.

Flexible installation, adaptable to various layouts

Wide axial movement for convenient adjustment

Compact structure with high strength and reliable sealing

Compatible with multiple pressure classes and flange standards

Effectively absorbs pipeline vibration and displacement

Extends the service life of the entire pipeline system

Thanks to these features, dismantling joints are widely used in municipal, industrial, and water supply projects.

Water and Wastewater Plants: Easily connect or remove valves for maintenance.

Pumping Stations: Installed at pump inlet/outlet to simplify equipment replacement.

Petrochemical Plants: Corrosion-resistant versions suitable for chemical pipelines.

Firefighting Systems: Used between pumps and valves for emergency access.

Urban Water Supply Networks: Increases flexibility and adaptability during upgrades.

With the expansion of infrastructure and complexity of industrial systems, dismantling joints are evolving toward:

Material diversification: From carbon steel to stainless steel and anti-corrosion alloys.

Enhanced sealing structures: Multi-layer seals to meet diverse media requirements.

Modular design: Standardized for easy installation and replacement.

Smart integration: Compatible with sensors for real-time pressure/sealing monitoring.

Eco-friendly production: Emphasis on energy efficiency and recyclable materials.

As a professional dismantling joint manufacturer, we provide:

A complete range of standard and custom dismantling joints

Options for PN6, PN10, PN16, ANSI 150, and other standards

Materials including carbon steel, stainless steel, epoxy-coated steel

Pressure and sealing tested for all products

Support for custom sizes, axial lengths, and structural types

Technical guidance, drawings, and fast delivery

Our products are exported globally to the Middle East, Southeast Asia, Africa, and Europe, widely used in infrastructure and industrial projects.

If you are seeking a reliable, easy-to-install pipeline connector for pumps, valves, or expansion compensation, feel free to contact us. Our team is ready to provide customized solutions and competitive quotes tailored to your project.