A metal expansion joint, also known as a bellows expansion joint or compensator, is a flexible component used to absorb dimensional changes caused by thermal expansion, mechanical vibration, or foundation settlement in pipelines, containers, or equipment. It consists of one or more bellows that utilize their elastic deformation to compensate for axial, lateral, or angular displacements, thereby protecting the system from stress damage.

Made from stainless steel and other high-strength, corrosion-resistant materials, metal expansion joints offer excellent temperature and pressure resistance and are widely used in industries such as power generation, petrochemicals, metallurgy, water treatment, district heating, marine, and construction.

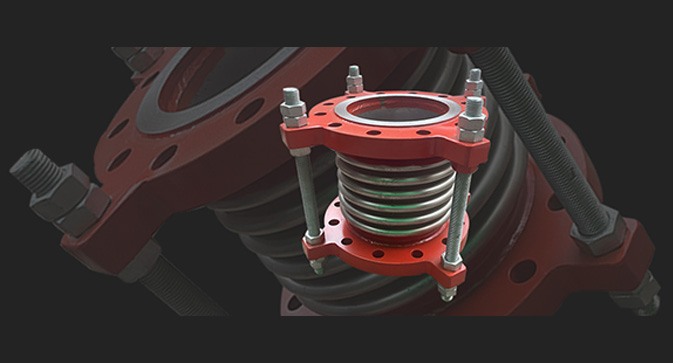

Bellows: The core component, usually made of multilayer stainless steel, offering excellent flexibility and resilience.

Inner Sleeve: Reduces fluid erosion on the bellows and extends service life.

Pipe Ends or Flanges: Connect to the piping system, available in welded, flanged, or threaded types depending on requirements.

Tie Rods or Limiters: Prevent the joint from exceeding the designed displacement during operation.

Absorb axial movement due to thermal expansion and contraction

Reduce mechanical vibration and protect adjacent components

Minimize operational noise and improve system stability

Compensate for installation misalignment and ground settlement

For example, in thermal pipelines, when temperature rises from ambient to several hundred degrees Celsius, significant pipe elongation occurs. Without proper compensation, this can lead to bending, rupture, or weld failure. Expansion joints effectively solve this issue.

Compact structure with excellent compensation capability

High temperature and pressure resistance for diverse applications

Long service life with low maintenance requirements

Easy installation, space-saving design

Customizable for specific working conditions

Compared to traditional solutions like sliding supports or rotary compensators, metal expansion joints require less maintenance and are more reliable for long-term operation.

Petrochemical Industry: Used in refining units and chemical pipelines to absorb thermal expansion and ensure system safety.

Power Generation (Thermal & Nuclear): Applied in boilers and high-temperature steam lines to reduce system stress.

District Heating: Compensate for thermal expansion in long-distance hot water transport pipelines.

Shipbuilding: Absorb vibrations and noise during equipment operation, protecting precision components on board.

With the rise of industrial modernization, demand for expansion joints continues to grow. Key trends include:

Customization: Tailored designs and structures based on different working conditions.

Advanced Materials: Use of Inconel, Monel, and other high-performance alloys for high-temperature, high-corrosion environments.

Integration of Smart Monitoring: Sensors for real-time monitoring of displacement and temperature to predict product lifespan.

Green and Sustainable Development: Improved sealing and lower energy consumption for eco-friendly applications.

As a professional manufacturer of metal expansion joints, we provide:

Standard and custom-designed expansion joints

Various connection types: flanged, welded, or socket-welded

Full technical support and selection guidance

100% pressure-tested products with complete quality reports

Compliance with GB, ASME, EN, ISO and other international standards

Our products are widely used and trusted in Southeast Asia, the Middle East, Europe, and other global markets.

If you are seeking reliable solutions for pipeline expansion, vibration control, or improving system lifespan, we are ready to help. Contact us today to receive professional consultation and tailored solutions.