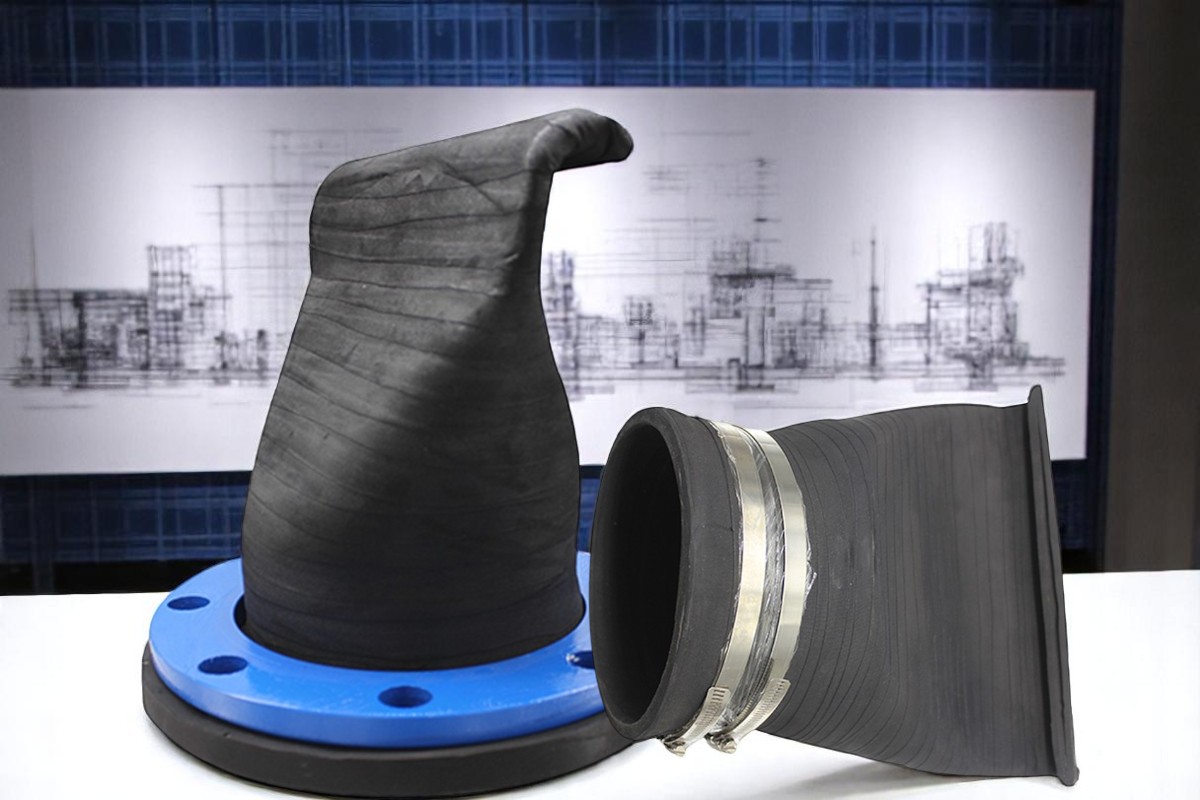

A Duckbill Check Valve is a backflow prevention device made of highly elastic rubber, designed to allow fluid to flow in only one direction. It gets its name from its duckbill-shaped outlet, which remains naturally closed without any external force. When forward pressure is applied from the system, the valve opens to allow flow; when reverse pressure occurs, the valve tightly seals to prevent backflow.

Compared with traditional metal check valves, duckbill valves have no mechanical parts, require no lubrication, and are silent in operation. They are highly resistant to corrosion and wear, making them ideal for applications such as stormwater systems, sewage treatment, tidal outfalls, chemical discharge, and coastal infrastructure.

A Duckbill Check Valve is typically molded from high-quality rubber materials. Common mounting styles include flange type, inline type, slip-on type, and wall-mounted type. The structure mainly includes:

Duckbill-Shaped Valve Body: Made from molded rubber with excellent flexibility and sealing performance.

Mounting Base: Flanged or slip-type connection for easy integration with piping systems.

Reinforcement Layer: Embedded fabric or steel to enhance strength and service life.

Tapered Discharge Design: Ensures low opening pressure and reliable sealing under backflow pressure.

Working Principle: When internal pressure exceeds external pressure, the duckbill opens, allowing fluid to pass through. When reverse pressure is applied, the valve lips are pressed shut to form a tight seal, preventing any backflow.

No power or manual operation needed: Fully automatic operation with zero energy consumption.

100% tight backflow prevention: Excellent sealing even under low pressure.

Ultra-low opening pressure: Operates at pressures as low as 0.01 bar.

Corrosion and aging resistance: Material options include EPDM, NR, CR, NBR, and Viton.

Maintenance-free: No moving parts, no grease, and no routine maintenance required.

Flexible installation: Suitable for horizontal, vertical, wall-mounted, or submerged use.

Silent operation: No impact noise, making it ideal for residential and urban environments.

Self-cleaning: Natural flexing action removes debris and reduces clogging.

Duckbill check valves are widely used in:

Urban Drainage Systems: Prevent stormwater or sewage backflow into streets or buildings.

Sewage Treatment Plants: For outlet structures, tanks, and discharge points.

Industrial Pipelines: Chemical discharge lines containing acids or alkalis.

Ports and Coastal Projects: For sea water outfalls and tidal backflow control.

Pump Stations and Culverts: Combined with gravity drainage or pumps.

Agricultural Irrigation: Prevents channel and field backflow.

Rainwater Collection Systems: Prevents contamination from back pressure.

| Feature | Duckbill Check Valve | Metal Check Valve |

|---|---|---|

| Operation | Fully automatic | Spring or gravity assisted |

| Sealing | Tight and elastic | May leak due to wear |

| Installation | Easy and flexible | Requires alignment |

| Maintenance | Maintenance-free | Requires regular service |

| Noise | Silent | Audible closing noise |

| Durability | Resistant to corrosion and clogging | Prone to rust and blockage |

Duckbill valves have become the preferred choice in many anti-backflow applications due to these superior performance characteristics.

With advancements in materials and increasing demand for green infrastructure, duckbill valve technologies are evolving:

Advanced composite rubbers: Enhanced chemical, abrasion, and temperature resistance.

Transparent body options: For easier visual inspection and maintenance.

High-pressure models: For industrial and challenging outfall conditions.

Seismic and impact-resistant design: Suitable for disaster-prone regions.

Eco-friendly, recyclable materials: Compliance with global environmental standards.

Modular quick-change systems: Reduced downtime and faster replacement.

As a professional duckbill valve manufacturer, we offer:

Multiple configurations: Flange, slip-on, wall-mounted, clamp-type, and hybrid designs

Size range from DN50 to DN2000, with full customization support

Material options: NR, EPDM, NBR, CR, Viton for specific applications

Suitable for fresh water, sea water, wastewater, and chemical effluents

Engineering services: Technical drawing support, design consultation, global delivery

All products undergo pressure, seal, and aging tests before shipment

If you’re looking for a cost-effective, backflow prevention solution that requires zero maintenance, duckbill check valves are the optimal choice. Contact us today to get detailed specifications, drawings, and a free quotation. We provide one-stop services for engineers, contractors, and municipal utilities.