A waterproof casing is a protective and sealing device installed at the point where pipelines pass through concrete structures such as walls, slabs, basements, tanks, pump rooms, or culverts. Its primary function is to prevent water seepage, protect pipelines from corrosion, and ensure structural integrity over time.

Waterproof casings are widely used in plumbing, HVAC, firefighting, ventilation, and other utility systems—particularly in damp or submerged environments. These devices create a sealed conduit through which pipes can safely pass, providing a durable, water-tight barrier that supports long-term stability and leak protection.

Depending on project needs and environmental conditions, waterproof casings come in the following common types:

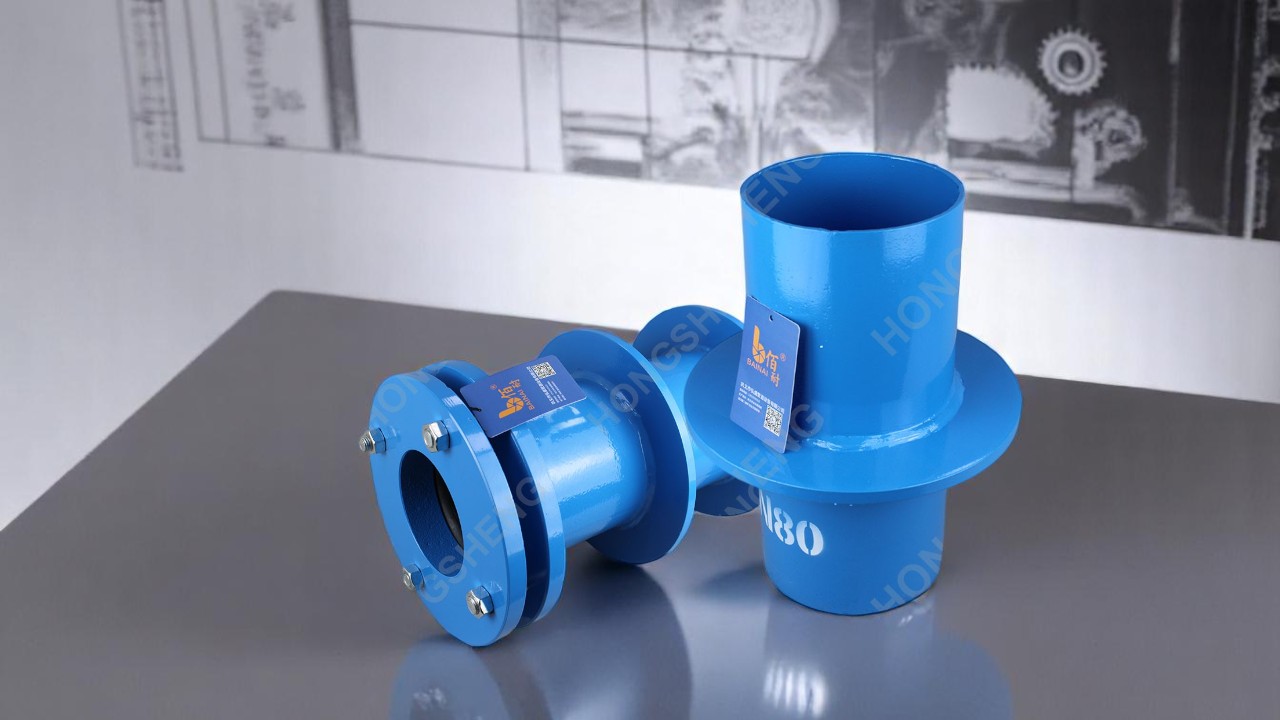

Rigid Waterproof Casing

Ideal for locations with no vibration or displacement. The gap between the casing and the pipe is sealed with flexible materials for reliable anti-seepage performance.

Flexible Waterproof Casing

Suitable for environments subject to vibration or slight pipe movement (e.g., pump stations or pipe corridors). It features a gland and rubber seal system for better adaptability.

Flanged Waterproof Casing

Designed with an external steel flange (or water-stop ring) that anchors into the concrete wall for improved sealing performance. Commonly used in tanks and high-pressure water environments.

Extended or Reducer Waterproof Casing

Customized casings with increased length or diameter variations to fit special wall thickness or multi-pipe layouts.

Typical waterproof casings include the following elements:

Casing Body: Made from carbon steel, stainless steel, or galvanized sheet metal with high strength and corrosion resistance.

Sealing Materials: Rubber gaskets, flexible sealants, or sealing pastes used between the casing and pipe.

Compression Gland (Flexible Types): Allows uniform pressure application for tight sealing and movement absorption.

Water Stop Flange: Ensures solid adhesion to concrete to block water seepage along the wall.

Sealing Principle: The system relies on mechanical compression or elastic sealing between the pipe and the casing. Combined with tight anchoring to the structure, it forms a reliable water barrier against seepage.

Excellent Waterproof Performance: Effectively blocks water infiltration through wall penetrations.

Easy to Install: Supports pre-embedding or post-installation methods, adaptable to various site conditions.

High Durability: Corrosion and aging resistant for long-term underground or submerged use.

Shock and Displacement Absorption: Flexible types handle vibration and minor shifts without damage.

Multiple Material Options: Carbon steel, stainless steel, or anti-corrosive coatings to suit different environments.

Standardized Production: Compliant with GB/T, CJ/T and supports custom designs for special applications.

Waterproof casings are used in a wide range of infrastructure and industrial projects:

Basements & Underground Garages: Prevent wall seepage in residential or commercial buildings.

Sewage Treatment Plants: Block leaks around pipe passages to avoid contamination or structural damage.

Water Tanks & Pools: Maintain sealed conditions in water-retaining structures.

Municipal Utility Tunnels: Seal pipe penetrations in manholes, culverts, and underground corridors.

Industrial Facilities: Used in steam, oil, or chemical pipelines passing through walls or slabs.

Firefighting Pipe Outlets: Provide sealed, fire-resistant penetration points across compartments.

Ensure correct axial alignment during pre-embedding. Avoid misalignment or displacement.

The casing surface should be roughened or fitted with anchors to bond with concrete.

Pipe and seal installation should follow immediately to avoid delayed water ingress.

In flexible types, ensure uniform bolt torque on the gland to prevent partial leakage.

Periodically check seals for aging, hardening, or dislocation.

For corrosive environments, use stainless steel or corrosion-resistant coatings.

Perform water pressure testing before waterproofing layers are applied in underground projects.

As a professional manufacturer of waterproof casings, we offer:

Full Series Supply: Rigid, flexible, flanged, anti-corrosion, and fire-resistant types.

Wide Material Options: Carbon steel, stainless steel, galvanized, or rubber-lined options.

Custom Fabrication: Based on drawings or special jobsite needs.

Accessories Provided: Rubber seals, anchor flanges, bolts, and installation kits.

One-Stop Engineering Support: CAD drawings, installation guidance, and system selection advice.

Factory-Direct Delivery: Fast production cycles and global shipping available.

If you’re working on underground construction, reservoirs, or piping through structural walls, our waterproof casing systems offer the reliability and performance you need. Contact us now for technical documentation, custom sizing, and a free quote. We’re ready to support your project from design to delivery.