With the continuous advancement of industrial automation, the requirements for flexibility, pressure resistance, and sealing performance in piping systems are becoming increasingly demanding. As a key flexible connector, the Flexible Metal Hose offers outstanding performance in high-temperature, high-pressure, and corrosive environments. This article will comprehensively explore its structure, advantages, application fields, and installation precautions.

Flexible metal hoses typically consist of:

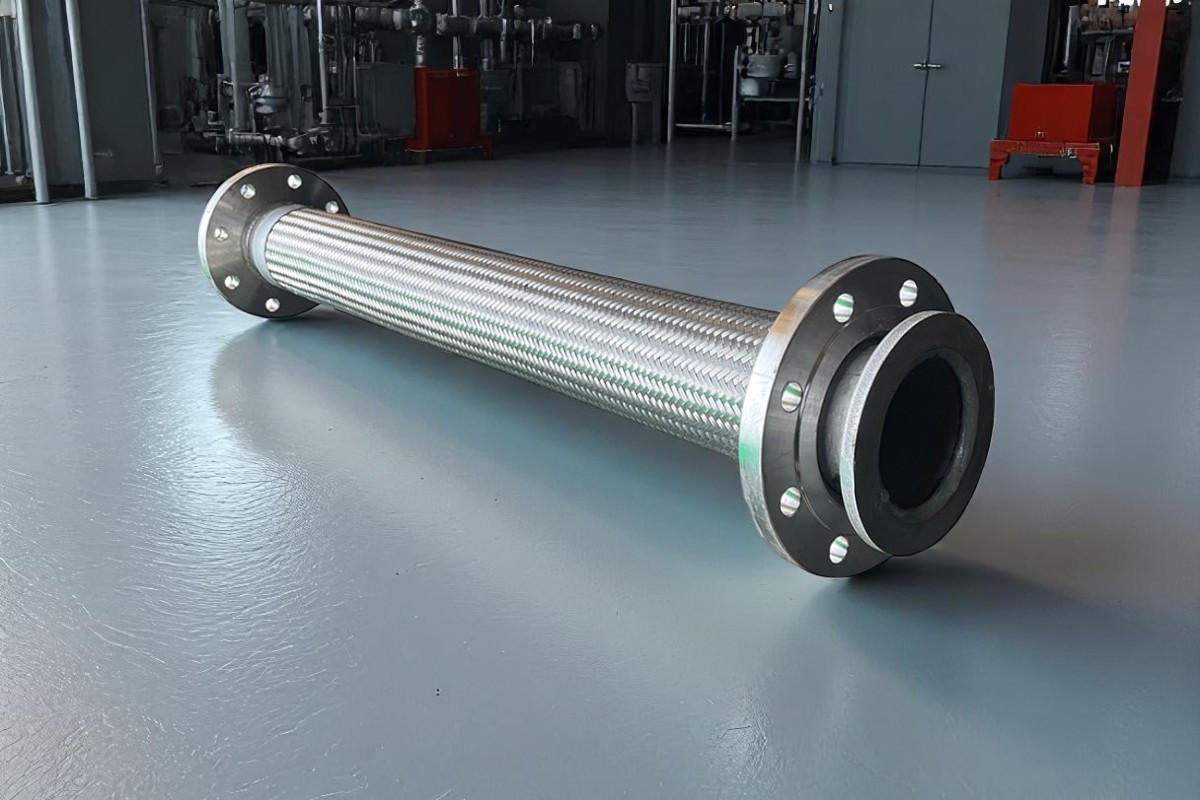

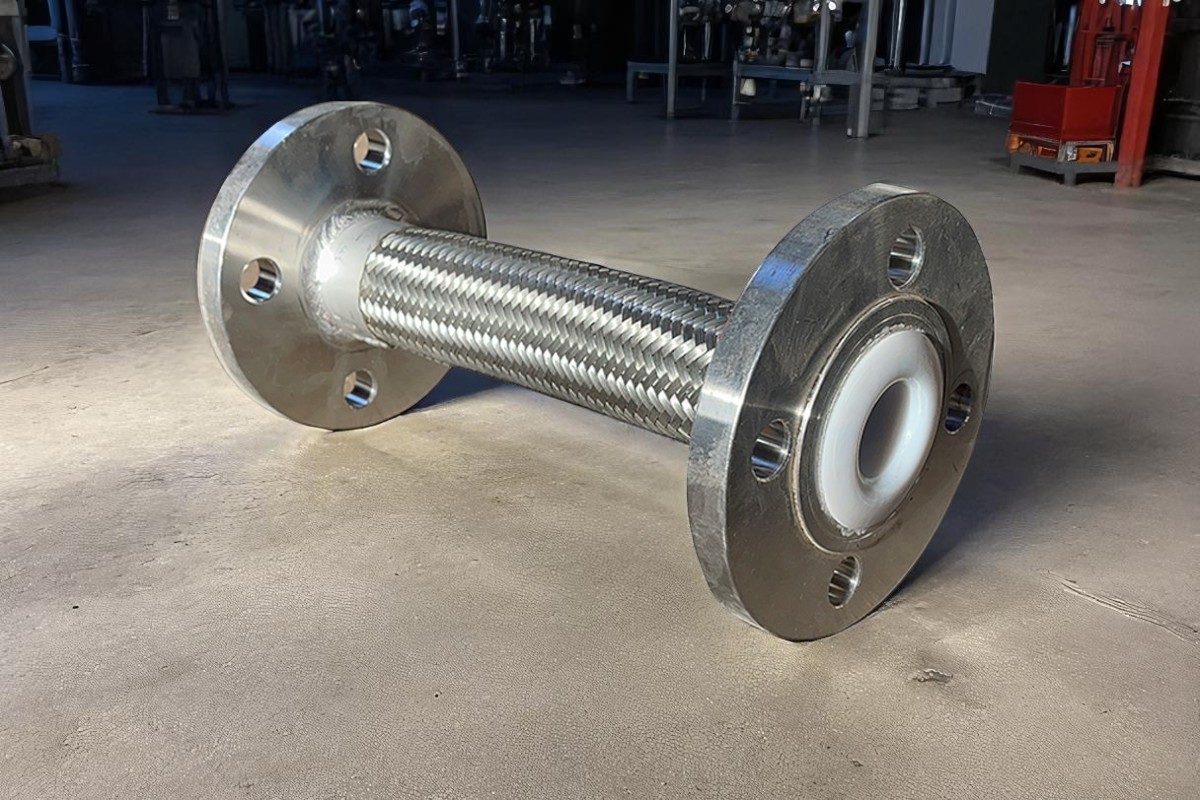

Corrugated Tube (Core Hose): Made from stainless steel or other metals, it provides both flexibility and pressure resistance.

Braided Layer: Stainless steel wire or strip braided mesh that enhances pressure capability.

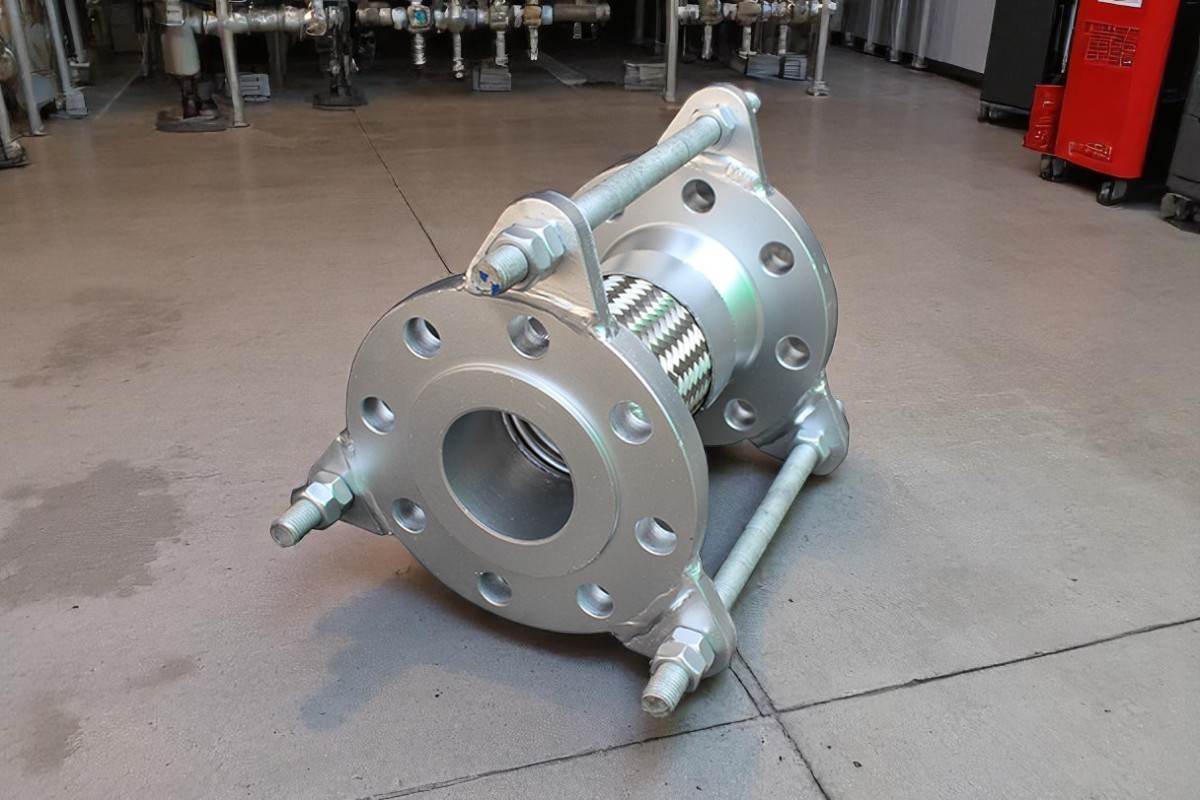

Fittings/Flanges: Various connection types such as flanged, threaded, or quick-connect ends are available to suit different systems.

This structure allows the hose to handle internal pressure while offering excellent compensation for axial, lateral, and angular movement.

High Temperature and Corrosion Resistance: Stainless steel construction withstands temperatures up to +500°C, ideal for steam, thermal oil, etc.

Vibration Absorption: Corrugated tube structure effectively absorbs mechanical vibrations.

Displacement Compensation: Handles thermal expansion, misalignment, or vibration-induced movement.

Excellent Sealing: Metal construction combined with precision welding ensures zero leakage.

Long Service Life: Designed for continuous operation in complex conditions with minimal maintenance.

Flexible metal hoses are widely used in:

Petrochemical Industry: For conveying corrosive fluids, solvents, oil, and gas.

Machinery Manufacturing: Ideal for connecting moving parts in machine tools.

Thermal Systems: Used in steam and heat transfer oil lines.

HVAC in Buildings: Connecting heat exchangers and air conditioning units.

Marine Industry: As vibration-absorbing connectors in ship engine rooms.

New Energy: In solar heating systems and thermal power generation applications.

Proper Sizing: Select based on working pressure, temperature, and flow rate.

Avoid Over-Bending: Always observe the minimum bending radius during installation.

Correct End Connection Alignment: Prevent twisting or torque stress during assembly.

Provide Adequate Support: Use support brackets to reduce stress on the hose.

Regular Inspection: Check for signs of abrasion, corrosion, or wear during maintenance cycles.

Flexible metal hoses provide unmatched performance in high-demand industrial environments. Their ability to combine flexibility, durability, and chemical resistance makes them a preferred solution across various sectors. Whether for new projects or system upgrades, flexible metal hoses are a wise and reliable choice.