In modern piping projects such as water supply and drainage, HVAC, power, and petrochemical industries, rubber expansion joints are widely used due to their excellent functions of vibration absorption, noise reduction, and displacement compensation. They not only effectively absorb movements and vibrations during system operation but also improve sealing performance and operational safety.

This article explains the structure, performance advantages, typical applications, and selection guidelines of rubber expansion joints, providing practical references for engineers and procurement professionals.

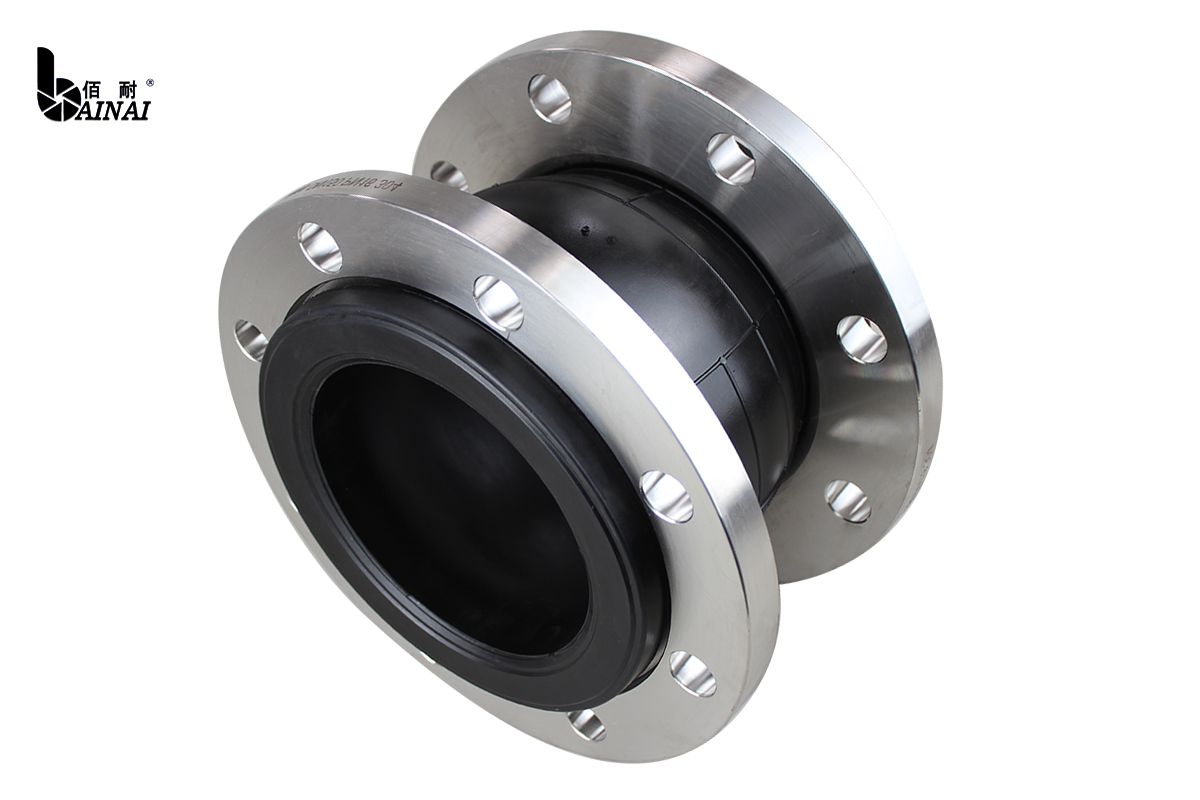

A rubber expansion joint is mainly composed of an inner rubber layer, reinforcement layer, outer rubber layer, and flange or threaded ends. Based on different requirements and working conditions, they can be classified into:

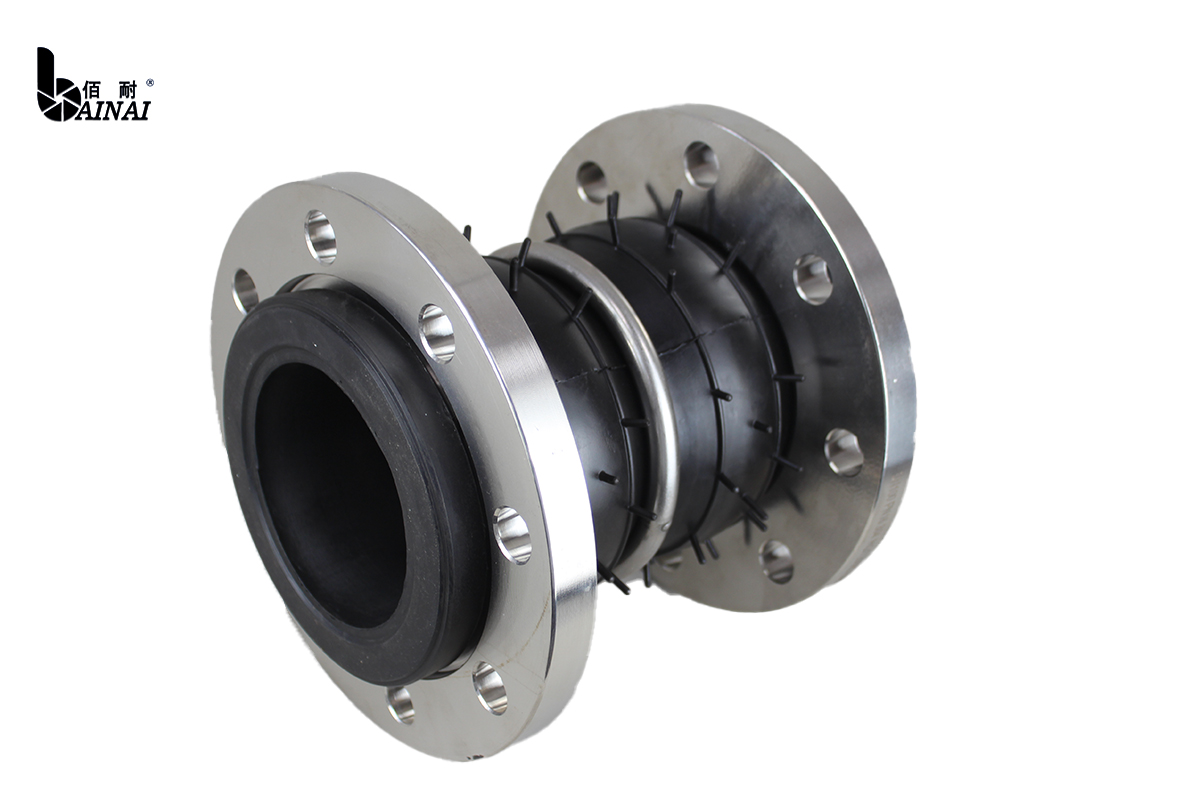

Single sphere expansion joint: Compact design, suitable for small displacement compensation.

Double sphere expansion joint: Larger compensation, better vibration absorption.

Eccentric/reducer type expansion joint: For pipelines with different diameters.

Special types: Acid/alkali-resistant, oil-resistant expansion joints for specific media.

Excellent Vibration Absorption

Effectively absorbs vibration from pumps, fans, and other equipment, protecting pipelines and valves.

Strong Displacement Compensation

Can absorb axial, lateral, and angular displacements caused by thermal expansion, contraction, or foundation settlement.

Superior Sealing Performance

Elastic rubber and reliable flange connection prevent leakage.

Wide Application Range

Suitable for hot/cold water, seawater, oil, acid/alkali solutions, compressed air, etc.

Easy Installation

Lightweight, flexible, and easy to transport, install, and maintain.

Municipal water supply & drainage: Installed at pump inlets/outlets to absorb vibration and compensate for movement.

HVAC systems: Reduce pump operation noise, improving comfort.

Power industry: Cooling water systems in power plants, reducing thermal expansion stress.

Petrochemical plants: Transporting oil, acids, alkalis with corrosion-resistant rubber joints.

Marine industry: Applied in seawater and engine cooling pipelines.

Medium Characteristics

Choose appropriate rubber material based on the medium (water, oil, acid, alkali, gas).

Temperature and Pressure

Confirm working temperature and pressure range to avoid exceeding limits.

Displacement Compensation

Select single or double sphere types depending on required movement absorption.

Installation Environment

For outdoor applications, use UV- and aging-resistant rubber materials.

Flange Standards,Ensure compatibility with pipeline flange standards (DIN, ANSI, GB, etc.

).