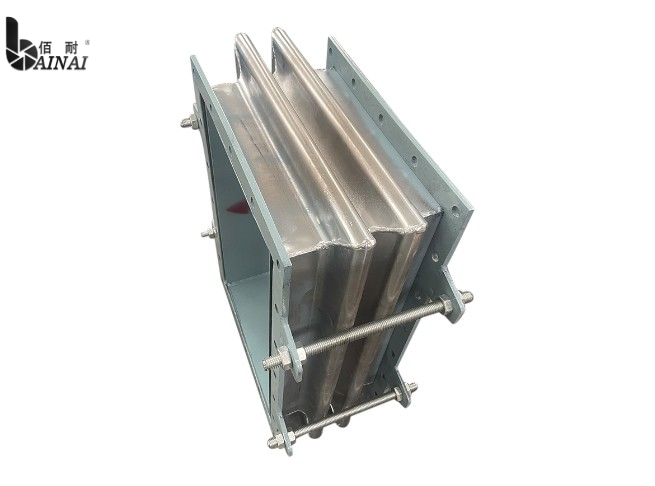

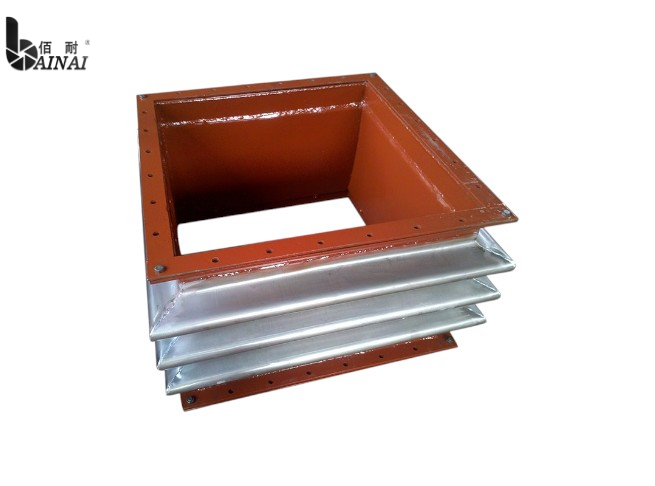

The rectangular corrugated expansion joint is a flexible connecting element designed to absorb thermal expansion and displacement in ducts, pipelines, or equipment. It is suitable for high-temperature, high-pressure, or vibration-prone environments. Through its metal bellows structure, it compensates axial, lateral, and angular movements, making it ideal for hot blast furnaces, dust removal systems, ventilation equipment, and various conveying pipelines. It effectively extends the service life of pipeline systems.

Our rectangular corrugated expansion joints are made from premium stainless steel, offering excellent corrosion resistance, fatigue strength, and flexibility. Multiple structural types are available, including single-wave, double-wave, and multi-wave designs, with optional flow guide sleeves, dust covers, and internal liners to meet diverse working conditions. All products undergo strict welding and sealing tests to ensure safety and reliability in operation.

Key characteristics include:

Compensation in multiple directions

Enhanced system sealing

Reduced vibration and noise transmission

Easy installation and maintenance

Suitable for rectangular or non-standard duct shapes

Rectangular corrugated expansion joints are widely used in the following industries and fields:

Power plants (flue gas and air duct systems)

Metallurgy and steel industries (hot blast furnace piping)

Petrochemical industry (exhaust gas pipelines)

Cement and building materials industries (high-temperature gas discharge systems)

Environmental protection systems (bag filter inlets and outlets)

HVAC and ventilation engineering

Strong Multi-Directional Compensation Capability

Capable of absorbing axial, lateral, and angular displacements simultaneously, suitable for complex working conditions.

Flexible Structural Design

Customizable in single-wave, double-wave, or multi-wave types with optional flow guide sleeves, dust covers, or internal liners.

High Temperature and Corrosion Resistance

Made from high-quality stainless steel (such as 304, 316L, 310S), suitable for high-temperature and corrosive environments.

Excellent Sealing Performance

Designed with welded or flanged sealing structures to ensure gas-tight performance and operational safety.

Vibration and Noise Reduction

Effectively reduces vibration transmission and noise, enhancing the overall system stability.

Easy Installation and Maintenance

Modular design allows for convenient installation, low maintenance frequency, and cost-effective operation.

Adaptability to Non-Standard Ducts

Specifically designed for rectangular or non-circular ducts in flue gas, hot air, and ventilation systems.